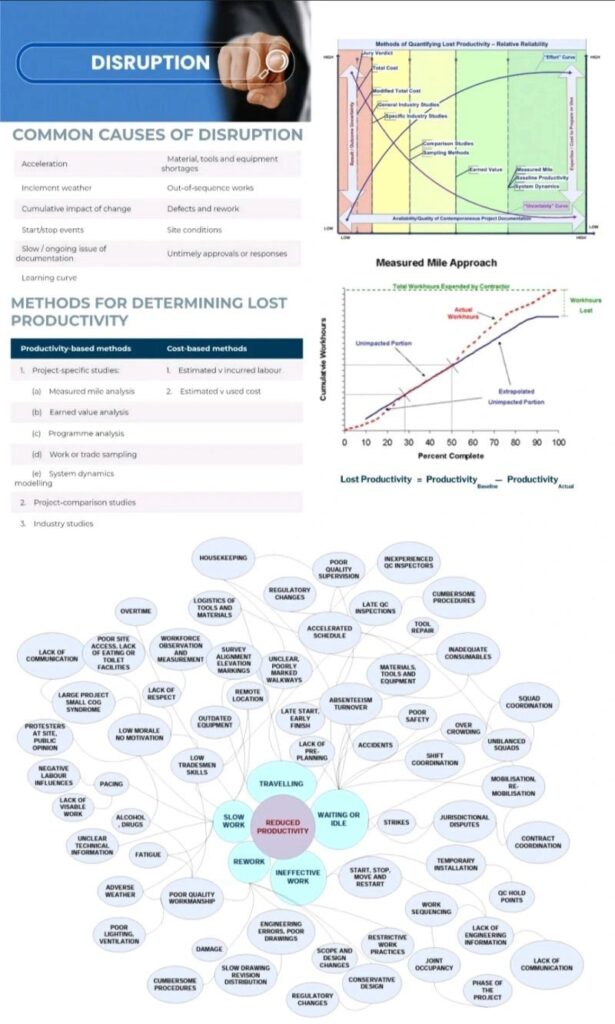

Loss of productivity, disturbance, hindrance or interruption to contractor’s normal working methods, resulting lower efficiency

?? ?????????? ??????????

If caused by Employer, it may give right to compensation either under contract or as breach of contract. However, you should know that

???????????? ???? ?????????? ??? ???? ?? ???? ???? ??????????, ??? ??? ??????????? ??

It’s possible for work to be disrupted & for contract still to finish by contract completion date. In this situation

“?????????? ???’? ???? ????? ??? ???, ??? ??? ???? ????? ??? ???? ?? ??????? ?????????? ?? ??? ?????????”

?????? ?? ??????????:

•Changes to working methods

•Changes to working conditions & sequence

Ex. change in sequence or priority of work making some works more onerous to perform

•Adverse weather

•Management characteristics

•Project characteristics

Contractor should provide evidence regarding:

1-Disrupted Trade/work progress

2-Impacted (when disrupted) & unimpacted period(s) on work

3-Additional manpower (& equipment) expended on disrupted trades

4-Evaluate difference between periods analysed

5-Events caused work disruption

??????? ??????????

It’s not easy to prove disruptions especially without very detailed records as this is your strongest method to prove disruption by keeping good records

A side form keeping a good records, contractor has to focus on Cause by identify & track through to effect

Disruption exists on Micro level:

•It takes place within working day

•It may come down to lost hours or minutes within a day

Common Disruption Quantification methods used to measure disruption

-Baseline productivity analysis

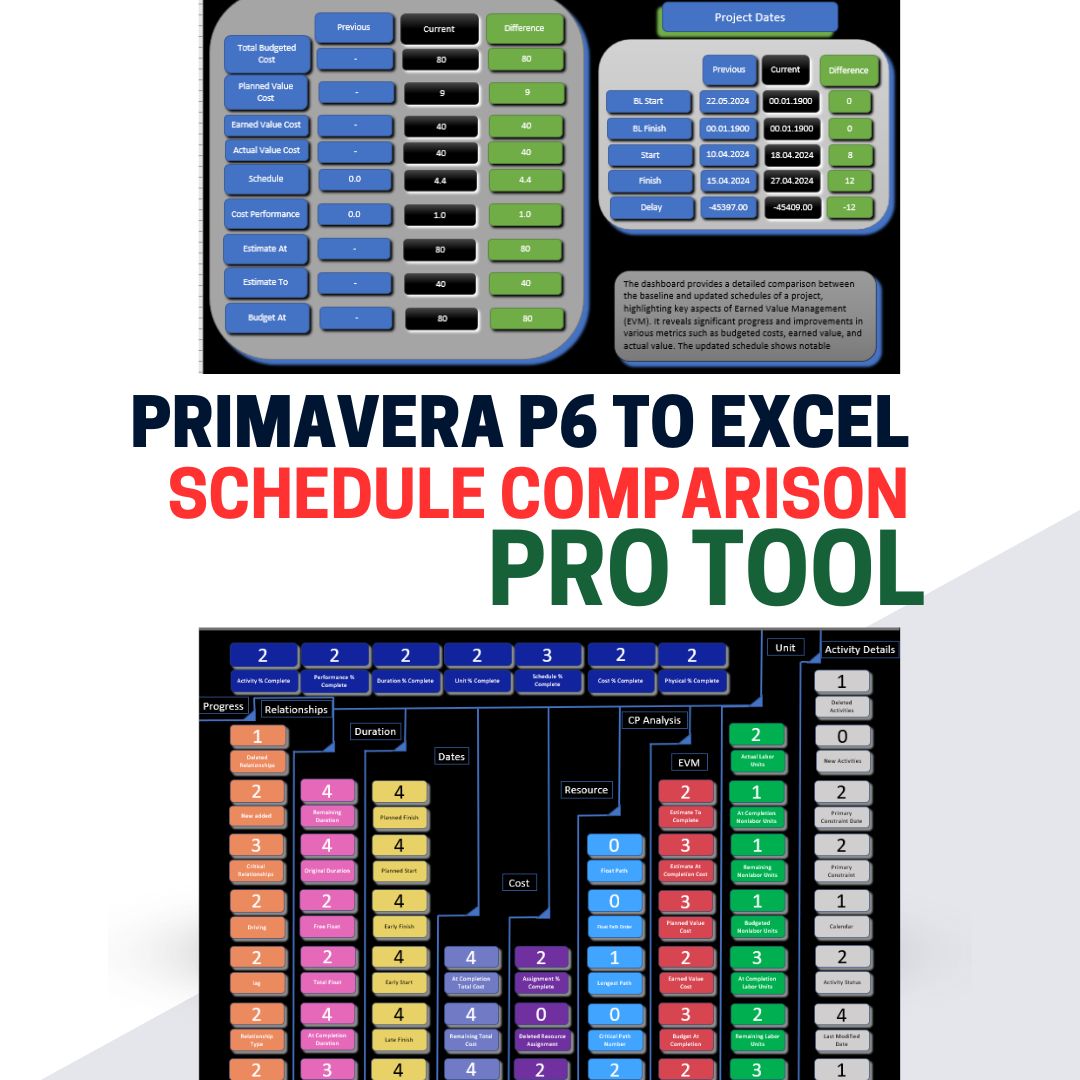

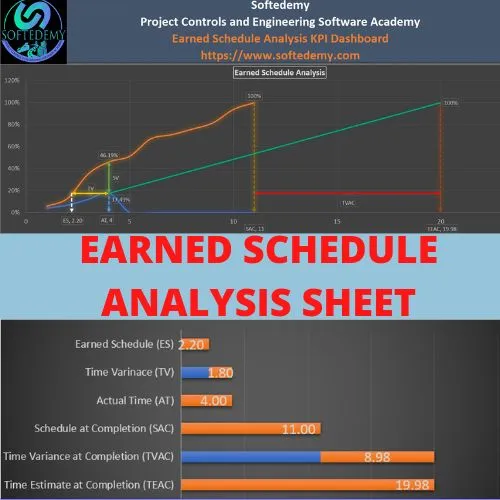

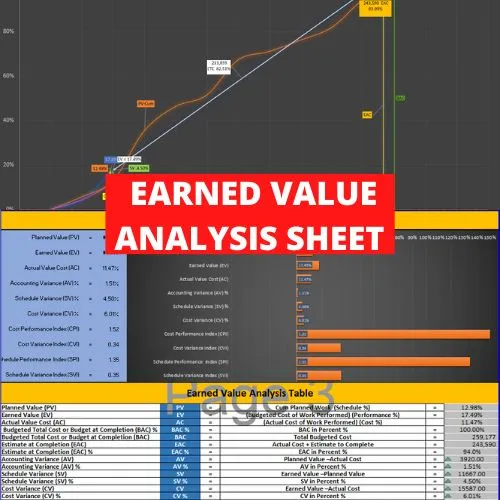

-Earned value analysis (EVA)

-Measured mile analysis

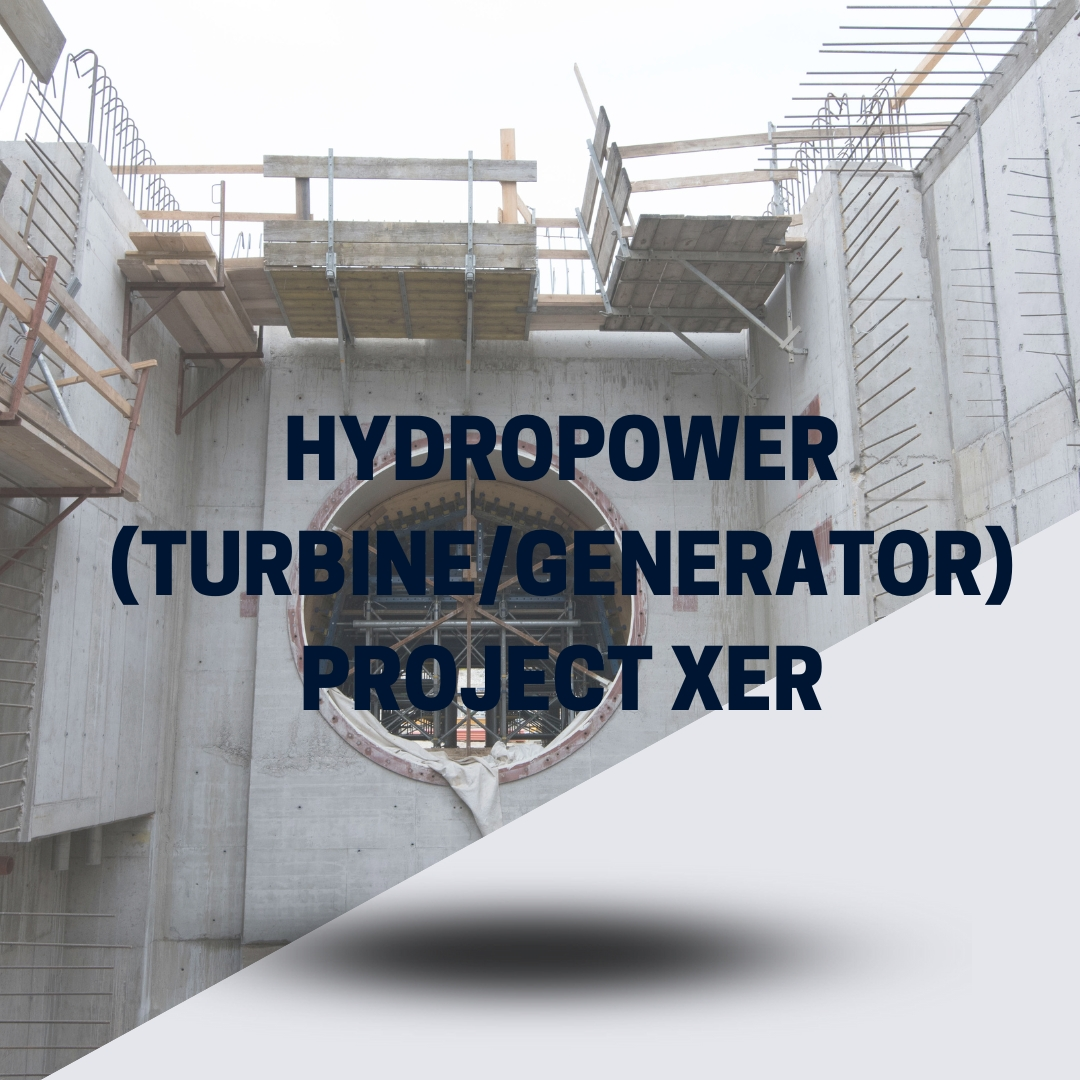

●???????? ???? ????????

Widely acknowledged as most acceptable method for calculating lost productivity costs

Analysis compares identical tasks in impacted & non-impacted periods of project to estimate productivity loss caused by impact of known series of events

Attraction of measured mile is that it compares actual performance on site with actual performance, not some theoretical planned performance

Productivity Change =

Unit Productivity during Impacted Period/Unit Productivity during Un-impacted Period

“There’s no fixed calculation method. But same principle applies, it’s very much dependent on nature of tasks as well as data available”

Calculation steps:

1》Identify Period Of Impeded Performance

2》Calculate Performance Ratio for Impeded Period

3》Calculate Performance Ratio for Un-impeded Period

4》Calculate difference between Performance Ratios

5》For disruption during Impeded Period:

Additional Cost or Resource to achieve a task due to Disruption = Performance Ratios X Planned Value Earned during Impeded PeriodLoss of productivity, disturbance, hindrance or interruption to contractor’s normal working methods, resulting lower efficiency

?? ?????????? ??????????

If caused by Employer, it may give right to compensation either under contract or as breach of contract. However, you should know that

???????????? ???? ?????????? ??? ???? ?? ???? ???? ??????????, ??? ??? ??????????? ??

It’s possible for work to be disrupted & for contract still to finish by contract completion date. In this situation

“?????????? ???’? ???? ????? ??? ???, ??? ??? ???? ????? ??? ???? ?? ??????? ?????????? ?? ??? ?????????”

?????? ?? ??????????:

•Changes to working methods

•Changes to working conditions & sequence

Ex. change in sequence or priority of work making some works more onerous to perform

•Adverse weather

•Management characteristics

•Project characteristics

Contractor should provide evidence regarding:

1-Disrupted Trade/work progress

2-Impacted (when disrupted) & unimpacted period(s) on work

3-Additional manpower (& equipment) expended on disrupted trades

4-Evaluate difference between periods analysed

5-Events caused work disruption

??????? ??????????

It’s not easy to prove disruptions especially without very detailed records as this is your strongest method to prove disruption by keeping good records

A side form keeping a good records, contractor has to focus on Cause by identify & track through to effect

Disruption exists on Micro level:

•It takes place within working day

•It may come down to lost hours or minutes within a day

Common Disruption Quantification methods used to measure disruption

-Baseline productivity analysis

-Earned value analysis (EVA)

-Measured mile analysis

●???????? ???? ????????

Widely acknowledged as most acceptable method for calculating lost productivity costs

Analysis compares identical tasks in impacted & non-impacted periods of project to estimate productivity loss caused by impact of known series of events

Attraction of measured mile is that it compares actual performance on site with actual performance, not some theoretical planned performance

Productivity Change =

Unit Productivity during Impacted Period/Unit Productivity during Un-impacted Period

“There’s no fixed calculation method. But same principle applies, it’s very much dependent on nature of tasks as well as data available”

Calculation steps:

1》Identify Period Of Impeded Performance

2》Calculate Performance Ratio for Impeded Period

3》Calculate Performance Ratio for Un-impeded Period

4》Calculate difference between Performance Ratios

5》For disruption during Impeded Period:

Additional Cost or Resource to achieve a task due to Disruption = Performance Ratios X Planned Value Earned during Impeded Period